According to a government survey from 2017, three-quarters of French people would be willing to pay more for a product made entirely in France, 95% believe that it's a way for supporting national industry and 87% think this will contribute to environmental protection.

Seen from abroad, Made in France is associated with luxury, originality and pleasure. In some countries, this label affixed to the product is enough to appeal to the consumer. What does actually the client try to acquire? Avant-garde aesthetics, style and special detailing. Obviously it is the French refinement that attracts him, a certain savoir-vivre anchored in a centuries-old heritage history. A heritage to be preserved

A heritage to be preserved

Buying a 100% French product means choosing to support a craftsmanship and industrial know-how forged for generations and intrinsically linked to the very history of the country. From a French standpoint, it can be considered a civic and cultural act. However, whether at the national or international level, any expertise is a legacy that must be safeguarded and passed on to future generations and be perpetuated by them. The technical skills acquired and developed in the various French industries are proven and it would be a pity if they were forgotten for letting proficient companies be in jeopardy.

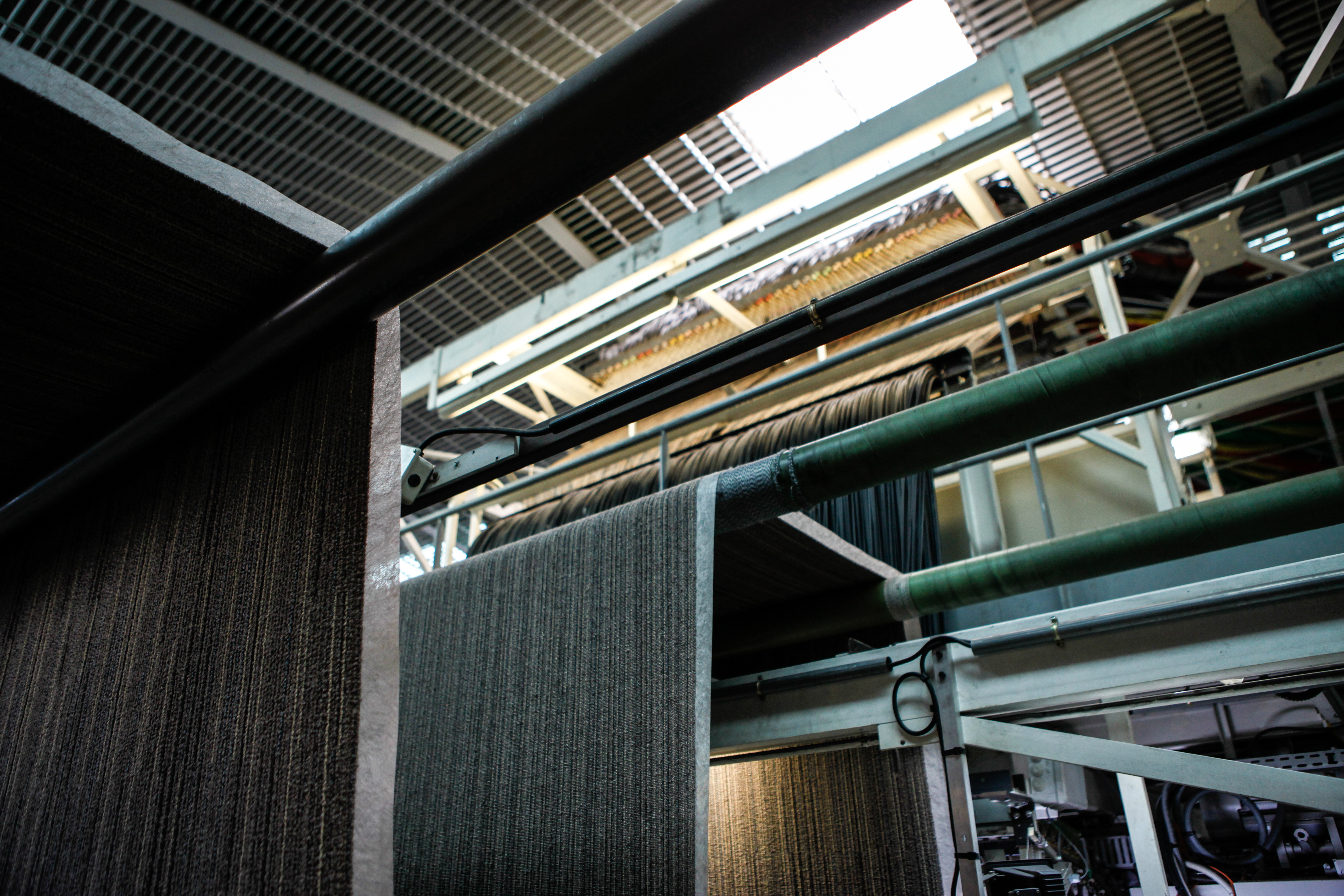

Tecsom is an industrial firm that has been in existence since 1881. It has obviously undergone transformations and adaptations in more than a century, but the fact remains that its present form cannot be cut off from its source. Our factory in Sedan, built in 1961, is equipped with a range of tufting machines whose driving has been passed on over generations and the technicians who supervise the production, wether in its manufacturing, quality control, storage or R&D, have real expertise.

Traceable quality and recycled materials

Made in France means quality production because the manufacturing process uses raw material collected in the country and easily traceable. Materials transport distances are reduced and, as a result, environmental contaminant emissions are minimized.

Most of the primary materials needed for TecSOM tiles manufacturing are collected from an area within 300 km of the production site. Our patented Backing System is made mainly from recycled materials and some of our collections are woven with fully recycled ECONYL yarns. Tecsom GREEN SYSTEM collection, for example, reaches 78.5% natural and recycled content.Tecsom acoustic underlay is produced with recycled fibres.

Eco-friendly accreditations

Today’s architectural projects should meet environmental standards in order to assess the buildings behaviour. Overall, the objective of these labels is to limit in the short and long term the impact of construction or rehabilitation operations on the natural environment, while ensuring healthy and comfortable living conditions for the occupants.

All Tecsom products are eligible for HQE (High Environmental Quality), LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment) certifications.